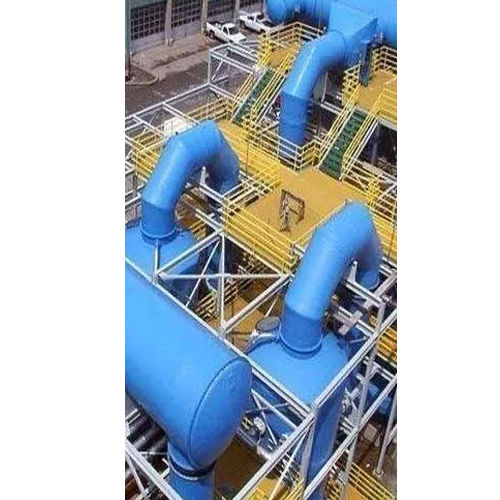

Industrial PP FRP Duct

Price 1000 INR/ Unit

Industrial PP FRP Duct Specification

- Connection Type

- Bolt-on Flange

- Tensile Strength

- ~60 MPa

- Bend Radius

- As per diameter (minimum 1.5xD)

- Flexibility

- Rigid

- Coating Type

- FRP Lining

- Sealing Type

- Gasket Sealed

- Diameter

- 250 mm - 1200 mm

- Temperature Range

- -10C to +120C

- Yield Strength

- ~25 MPa

- Tolerance

- 2 mm

- Product Type

- Industrial Duct

- Connection

- Flanged

- Shape

- Round

- Standard

- ASTM D4101 / IS 12709

- Surface Treatment

- Smooth Finish

- Outer Diameter

- Up to 1200 mm

- Section Shape

- Circular

- Length

- Up to 6 meters (customizable)

- Thickness

- 5 mm - 10 mm

- Color

- Grey

- Rated Pressure

- 0.5 - 2.5 bar

- Application

- Chemical, Pharmaceuticals, Waste Gas, Fume Extraction

- Material Grade

- PPH/FRP - Industrial Grade

Industrial PP FRP Duct Trade Information

- Minimum Order Quantity

- 10 Units

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Industrial PP FRP Duct

Industrial PP FRP Duct is a type of ductwork used in various industries to transport gases, liquids, and fumes. It is a composite material that combines the strength and durability of fibreglass with the chemical resistance of polypropylene. Industrial PP FRP Duct is best known for its excellent resistance to corrosion, abrasion, and high temperatures, making them ideal for use in harsh environments. These are also lightweight and easy to install, making them a popular choice for many industrial applications.

Outstanding Chemical & UV Resistance

Our PP FRP ducts are engineered to excel in corrosive environments, with high resistance against aggressive acids, alkalis, and organic solvents. UV-resistant properties protect against sunlight-induced degradation, ensuring extended service life during outdoor or exposed installations.

Customizable and Lightweight Design

Available in various sizes and thicknesses, our ducts can be tailored to your project needs. The lightweight construction simplifies handling, installation, and relocation compared to traditional metal ducts, reducing labor and transportation costs without sacrificing strength.

Low Maintenance with Superior Performance

These ducts require minimal maintenance due to their smooth inner surface, which reduces pressure loss and particle build-up. Flame retardant and gasket-sealed designs promote safe, reliable use in critical industrial processes, compliant with ASTM D4101 and IS 12709 standards.

FAQs of Industrial PP FRP Duct:

Q: How do I install the industrial PP FRP duct in my facility?

A: Installation is straightforward due to its lightweight, rigid structure and bolt-on flange connections. Simply align the circular sections, seal with the provided gasket, and secure using bolts. Its portable design enables easy placement and relocation as required.Q: What specific industries benefit most from using PP FRP ducts?

A: These ducts are particularly suitable for chemical processing plants, pharmaceutical industries, and waste gas or fume extraction systems, where resistance to corrosion and aggressive chemicals is vital for safety and operational efficiency.Q: When should I choose this product over traditional metal ductwork?

A: Select PP FRP ducts when your processes involve corrosive gases or harsh environments that could degrade metal. Their flame retardant, UV-resistant, and low maintenance properties provide long-term cost and safety advantages over conventional ducts.Q: Where can the duct be installed for optimal performance?

A: Install these ducts wherever corrosion, UV exposure, or flame safety are concerns, such as outdoor environments, laboratories, or industrial production lines. Their adaptability and customizable sizing make them versatile across varied industrial settings.Q: What is the process for customizing the duct to my requirements?

A: Provide your required diameter (from 250 mm to 1200 mm), thickness (510 mm), and length (up to 6 meters per section). The manufacturer will tailor the product, including surface treatment, connection type, and flange arrangement, to fit your exact needs.Q: How does the smooth inner surface benefit industrial operations?

A: A smooth internal finish reduces pressure drop and minimizes particle adhesion, improving airflow efficiency, reducing energy consumption, and lowering the risk of clogging within ventilation and extraction systems.Q: What are the main benefits of flame-retardant and UV-resistant properties?

A: Flame retardancy offers enhanced fire safety, reducing hazards in high-risk environments. UV resistance ensures the duct remains durable during prolonged sunlight exposure, making it reliable for both indoor and outdoor applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PP - FRP Duct Category

Industrial PP FRP Ducting

Price 1000 INR / Unit

Minimum Order Quantity : 10 Units

Usage : industrial

Material : Aluminum

Installation Type : Portable

Material Grade : frp

PP FRP Ducting Bend

Price 50000 INR / Unit

Minimum Order Quantity : 10 Units

Usage : Industrial

Material : Aluminum

Installation Type : Portable

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS